While most people buy ready-made exhaust pipes, you can opt to make one for yourself.

But is it possible? Can you make your own exhaust pipe? You can use an exhaust pipe kit to make your own exhaust pipe.

- Measure the pipes to the desired lengths and cut them with a power tool.

- Fit them beginning from the exhaust header to the tailpipe.

- Weld the parts together and fit them.

Making an exhaust system is not complicated, especially if you have basic vehicle knowledge. Read on for a detailed guide.

What You Need to Make Your Own Exhaust Pipe

Tools and materials needed for the project can determine your success. In the preparation phase, plan and gather everything you will use to make the exhaust pipes. Various materials will be needed, whether you’re making exhaust for a bike or a car. Following are the things you’ll need to make a custom exhaust system.

1. Universal Exhaust System

The universal exhaust system is a kit with several pipes, mostly made from aluminized steel. Most kits include four pieces of 45 degrees bend pipes, 90 degrees pipes, four four-foot sections, and U-pipes. Some may include Y or X pipes, and clamps, depending on the type of exhaust you intend to build. And the advantage of the universal kit is you don’t have to have a tool bender to bend the pipes.

2. Exhaust Bends and Elbows

These components help you create bends and angles in the exhaust pipe to fit the undercarriage of your vehicle.

3. Exhaust Clamps

These are used to secure sections of the exhaust pipe together.

4. Exhaust Hangers

Hangers are necessary to support the exhaust system and prevent it from hanging too low.

5. Measuring Tools

Making a custom exhaust pipe involves a lot of measuring for accuracy. Various measuring tools are needed, including framing squares and a digital angle finder. A tape measure is also required to measure the lengths of the pipes.

6. Angle Grinder

After measuring, the angle grinder cuts the pipes to the required sizes and shapes. Remember to buy some blades and discs to use on the angle grinder.

7. Welding Machine

You’ll need to buy or hire a welding machine if you don’t already have one. The machine is needed to connect the pipes after measuring and cutting. A Tig and Mig welding machine would be an ideal choice for this project.

8. Band Saw

A band saw will be used for cutting, especially if you’re needed to cut the pipes at precise angles. For instance, when creating a custom bend on the pipe, you can measure and cut with the band saw.

How to Make Your Own Exhaust Pipe? – Steps to Follow

With the tools and materials ready, it’s time to begin the actual process and make the exhaust pipes. You will group the process into four parts.

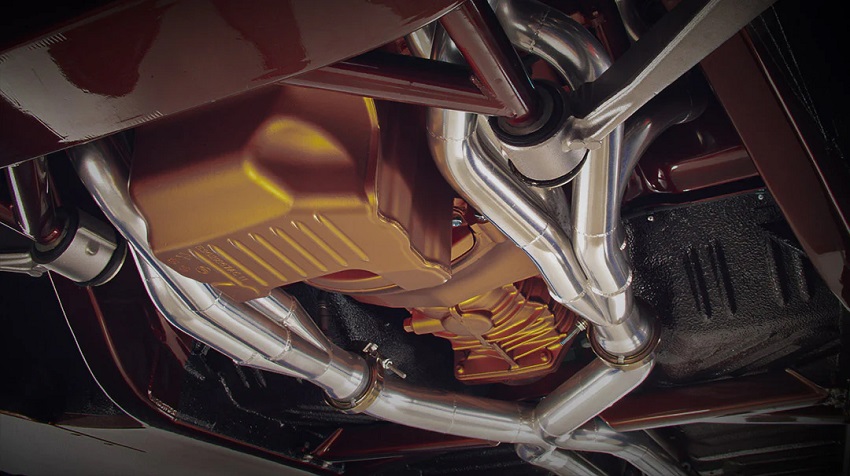

The following video will guide you while making the exhaust pipes

1. Measuring

For the measuring phase, you’ll utilize your measuring equipment to prepare the pipes. Fitting the exhaust pipes usually starts from the catalytic converter, where your first part is clamped. Measurements should begin from here.

- Step 1: Whether your exhaust system uses a Y or X pipe, measure the part between the exhaust system to fit perfectly. Some vehicles require an angled Y pipe, which you can make using two 45° pipes.

- Step 2: Use the angle finder to measure around corners and determine the degrees to cut the pipes.

- Step 3: Also, use the measuring tape to measure the length of the pipes needed. Remember not to cover other parts of the vehicle and bend around them.

2. Cutting

Using the measurements and markings on the pipes, cut and prepare them.

- Step 1: Use the angled grinder to cut through the pipes to the required lengths. For a more accurate cutting, use the bandsaw. For instance, when you want to create an eight-degree bend on the pipe, you must use the bandsaw.

- Step 2: While cutting, you should check and confirm each part’s match by holding them in position.

3. Welding

With the parts ready, use your welding machine to connect the parts. You may need to do tack welding first in case the measurements are wrong. Tack welding will allow you to cut and change the miscalculated parts.

For instance, the first part should be two straight pipes connecting to the catalytic converter or exhaust head pipes. The parts connecting to these straights are the Y or X pipes.

In the case of a Y pipe, a single straight pipe follows until there’s a need to curve. The parts follow straights and curves from here until the final straight at the end. If your system uses an X pipe, the process is the same, though using two pipes each time.

After ensuring the parts are well-fitted and not hindering other car parts, begin the actual welding. The Tig welding process is usually the most used to connect these parts.

Follow the steps below.

- Use clamps to hold the two pieces you’re about to weld

- Position the electrode of your welding machine’s head between the two parts you’re about to weld

- Bring the welding wire close to the welding head, and the two parts

- Just as you squeeze the trigger on your welder feed in the wire

- In Tig welding, the wire is fed slowly so make sure it’s not continuous as in Mig welding.

- Weld around the part while alternating sides to allow fair distribution of heat.

- Repeat the process for other parts.

4. Fitting

4. Fitting

When the welding process is complete, and the exhaust pipe is a single part, begin the fitting process.

- Step 1: Use exhaust hangers and clamps to hold the exhaust pipe in place.

- Step 2: If your exhaust system involves two pipes, like the case of X pipes, you may need to weld them together.

- Step 3: Weld the pipes with a piece of stainless steel to minimize movements against each other.

Is It Worth Making Exhaust Pipe Instead of Buying it?

Various factors can help you determine whether it’s worth making the exhaust pipes instead of buying a new one. They include:

Cost

If the total cost of making the pipe is less than that of buying a new one, it’s worth it. Most times, the needed parts range between $150 and $300. With the cost of a new exhaust averaging at $330, the cost is worth it.

Equipment and Tools

The process is only worth it if you already own various equipment and tools needed to make the exhaust pipes. However, if you have to buy the equipment too, the cost may rise and make it not worth it.

Time

The whole operation of making the exhaust pipe is time-consuming and can take a few days to complete. If you have time to spare and enjoy the process, it’s worth making the exhaust for your car. Conversely, you’re better off buying the part if time is limited.

Customize

One of the joys of making exhaust pipes is the ability to customize them at no extra cost. You can make the exhaust wider and louder and add other customizations.

Advantages of Making Your Own Exhaust Pipes

The following are various advantages of making and using your own exhaust pipes.

- Allows You to Customize the Exhaust Pipes

Making DIY exhaust pipes allows you to customize them to your liking. You can make them louder and big as you see fit. You can use any material compatible to make a unique exhaust system.

- Cheaper

If you already have the equipment needed, the overall price of making your own pipes is cheaper. You’ll only need to buy the universal exhaust kit for a price between $90 and $200.

- Allows You to Hone Your Skills

If you love making DIY custom parts, making the exhaust pipes can be a chance to improve your skills. The measuring, grinding, and welding will only add to your experience.

Downsides of Making Your Own Exhaust Pipe

While making a custom exhaust pipe has many advantages, there are also several disadvantages. They include

Time-Consuming

One of the downsides of a custom exhaust pipe is that making one is time-consuming. The time taken depends on your experience and the tools at your disposal.

Requires Costly Equipment

To create the exhaust pipes, you need a welding machine, which can cost ranges between $200 and $400. You will also need an angle grinder, costing between $30 and $100. If you don’t have any of the parts, the whole operation may become way costlier.

Requires Basic Mechanic Knowledge

A person without the knowledge may have difficulties making the pipes. Also, if they succeed, the pipes may become a ticking time bomb, and when they fail, they can cause costly damages.

Damage risk

The exhaust pipes often become hot when the vehicle is running. If you install them wrongly and they’re resting on other parts under the car, they may cause damage. Also, if not well planned for during installation, they may hinder other parts and must be removed during servicing.

Conclusion

For DIY enthusiasts, there’s nothing better than creating a custom part. When it comes to the exhaust pipes, the case is the same. The article covers various things you need to create a custom exhaust pipe for your vehicle.

Also, there are various things to consider to answer the question, is it worth making your own exhaust pipes? However, for some people, the answer is always yes, no matter the cost. Just beware of the various downsides discussed in the article, especially if you’re a first-timer.